A UNIQUE PASTA COMES FROM PRECISE CHOICES

We take nothing for granted when we process our pasta. Every stage, every process draws both on ancient experiences and recent discoveries, as well as on an original interpretation of taste. Our passion for our work translates into a ceaseless quest for perfection. To that end, we select raw materials of demonstrably superior quality, which we process using our own tailored procedures, and very particular preferences. In this section of the website, we describe our choices, which have made Pasta Garofalo unique since 1789.

OUR STORY

OUR PHILOSOPHY

Our sustainability commitment

High quality and safe products, people-centered culture, respect for the environment: these are the cornerstones of our commitment. Discover more exploring our first sustainability report, drawn up in collaboration with Lifegate.

FIRST CHOICE

ARE ALL SEMOLINAS THE SAME?

Absolutely not! And their differences are particulary noticeable in pasta, which is made from a single ingredient.

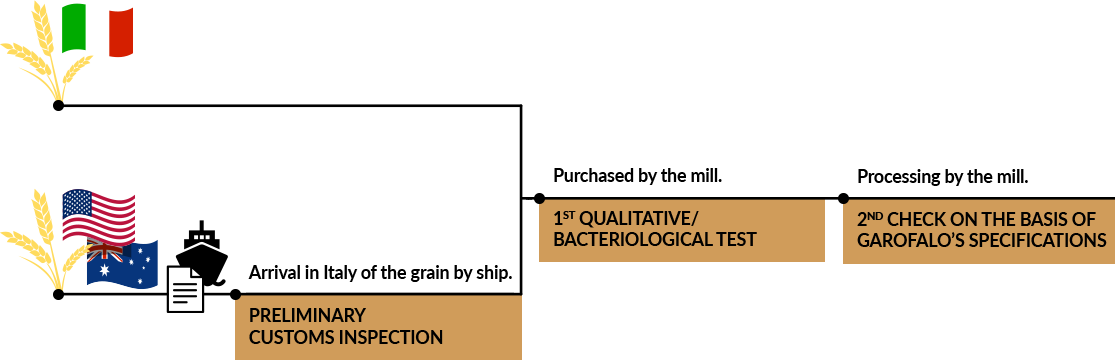

For this reason, we consider selecting the raw material for Pasta Garofalo to be crucial, and only use first class semolina, produced from "Desert Durum" wheat from Arizona (USA), as well as the best Australian and Italian grains. None of the grains that we choose are treated with a pre-harvesting method, i.e. early drying ears to prevent them being exposed to temperatures that are too harsh before harvesting. The Arizona desert climate, for example, guarantees protection from rain and temperatures that are too low, preventing the growth of weeds and rendering pesticides unnecessary. Needless to say, we have the pasta we're looking for in mind from the very first moment, so we only choose wheat that, in addition to a specific gluten level, offers a particular colour, cleanliness and flavour characteristics. These are essential to give Pasta Garofalo its distinctive character.

DID YOU KNOW THAT GLUTEN PLAYS A LEADING ROLE?

It's true, as many of the finished product's characteristics depend on the quality of gluten.

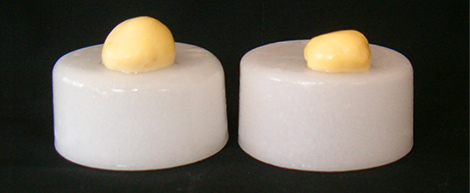

This is because the gluten creates the protein network that retains starch, the main energy component of pasta. The unique traits of Pasta Garofalo not only depends on the quantity of gluten, which is expressed indirectly on the pasta pack under the heading "Protein level" (in our case, at least 14%), but above all, on its quality, or gluten index (to check the gluten index of our pasta, see the semolina analysis in the section Where does our semolina come from? The gluten index indicates the elastic property of the protein network, which plays a key role in obtaining pasta of outstanding firmness, even past the ideal cooking point. In fact, the texture during chewing is a fundamental element of Garofalo Pasta, as well as its ability to remain "lively and in proper shape" in the dish, even a few minutes after being drained. These qualities derive from the gluten contained in our semolina of choice. In addition to the analytical proof, its superiority becomes evident in a simple photographic comparison.

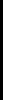

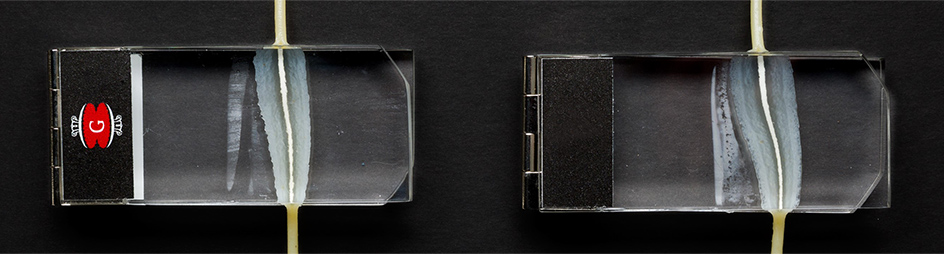

When semolina is dissolved in water, there is only one gluten ball left, which constitutes its non-soluble component. On the left, we can see the gluten extracted from Garofalo's semolina, which forms a larger, high and elastic ball. Conversely, gluten extracted from medium quality semolina, shown on the right, has less elasticity and resistance, and does not form a regular ball.

When semolina is dissolved in water, there is only one gluten ball left, which constitutes its non-soluble component. On the left, we can see the gluten extracted from Garofalo's semolina, which forms a larger, high and elastic ball. Conversely, gluten extracted from medium quality semolina, shown on the right, has less elasticity and resistance, and does not form a regular ball.

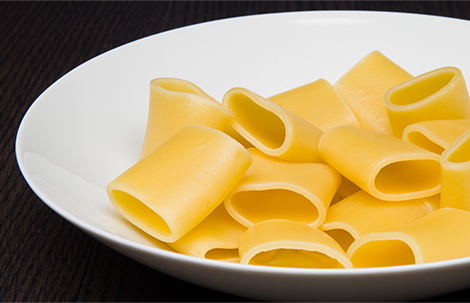

Two pasta dishes made with exactly the same machinery and following the same production process, but with different semolina:

Garofalo's semolina

medium-quality semolina

The difference is evident, particularly as regards the firmness and liveliness of its shape.

Two pasta dishes made with exactly the same machinery and following the same production process, but with different semolina: Garofalo's semolina on the left, and medium-quality semolina on the right. The difference is evident, particularly as regards the firmness and liveliness of its shape.

TRADITION DRAWS ON INNOVATION

WAS PASTA OF THE PAST BETTER?

No, it's useless idealising the past: today's pasta is simply better.

The pasta production process has been the same for centuries, but research and technology have made it more efficient, whilst innovation has allowed the pasta industry to progressively improve the quality of its products. Research is not just about grain selection, as we've already seen, but also involves the development of equipment. Given our current tastes, the best pasta produced a hundred years ago would be considered inedible. But it's not just that: Thanks to technology, the pasta on our tables today is better than the pasta produced fifty, twenty or even ten years ago. The same applies to hygiene and food safety: Over time, the tools at our disposal have been refined, and current controls throughout the supply chain are more accurate and reliable than ever before.

An advert for Pasta Garofalo from the Eighties

A snapshot from today

Which one would you choose? Can you see the differences in quality?

An advert for Pasta Garofalo from the Eighties and a snapshot from today. Which one would you choose? Can you see the differences in quality?

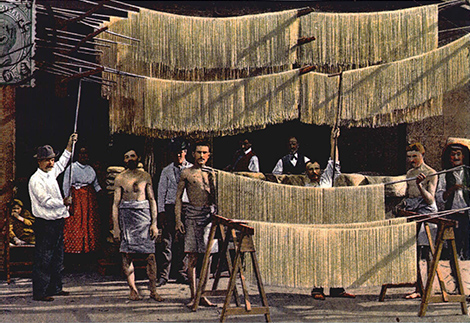

The traditional drying of pasta, under poor hygienic conditions

The drying process today, in the protected environment of our factory

On the left, the traditional drying of pasta, under poor hygienic conditions; on the right, the drying process today, in the protected environment of our factory.

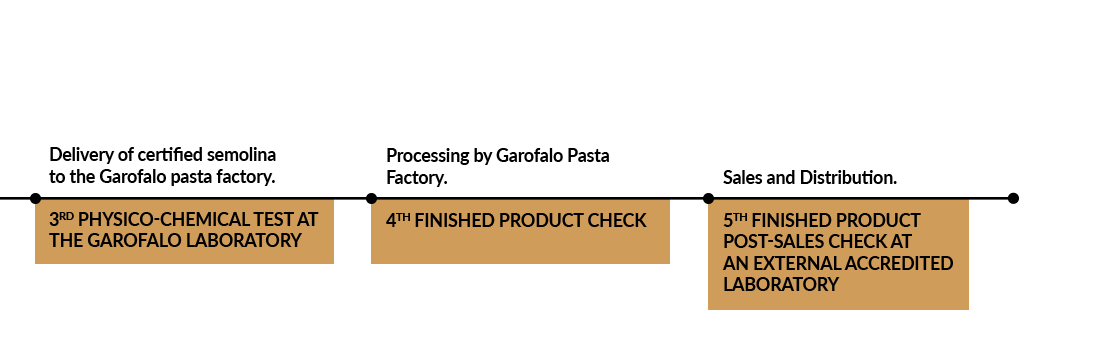

MONITORING

BUT DOES THE CHECKING EVER FINISH?

That's right, excellent pasta can only come from a continuously monitored process.

To this end, after carefully selecting the raw materials for our pasta, we closely monitor it as it moves through the entire production process. We have established and agreed on an uncompromising checking system with the Italian mills we use for our milling: every step, from the arrival of the wheat to the delivery of semolina to the pasta factory, undergoes cross-checking. A further round of checks takes place inside the pasta factory, and once our pasta is packaged and distributed, we still monitor it using sample testing on the finished product. Only in this way can we guarantee the excellence of our product, both in terms of quality and food safety, and thus ensure that only the best reaches your table. Because the check we care about most is your own, every time you enjoy Garofalo Pasta.

DOUGH

IS GOODNESS PRIMARILY A MATTER OF RESPECT?

If we start with an excellent ingredient, we must do our best to preserve its quality.

From the start of the production process, when the durum wheat semolina is mixed with water, our main concern is to respect the raw materials we have selected so carefully. Because the attention paid to the dough determines the porosity of the final product (i.e., the quality of pasta that has to bind to the sauce). At this stage, our goal is also to preserve the natural colour of the grain. Respect, in this sense, means avoiding water that has too high a temperature, which would compromise the original quality of the semolina, as well as using extra water to ensure the porosity that distinguishes Pasta Garofalo.

DRAWING

IS THE SHORTEST PATH ALWAYS THE BEST?

Not necessarily, sometimes quality lies at the end of a winding track.

For many of our pasta shapes, we seek to produce the maximum thickness possible ("cartella" is the technical term) when drawing the dough, despite the fact that this complicates and lengthens the next stage, i.e. drying. To provide specific information about the thickness we're seeking, we specify the dimensions of our spaghetti range.

Even when cutting the penne pasta format and its ridges, we are not satisfied easily, but relentlessly seek perfection. We constantly check the drawing dies (the part through which dough passes to take its shape) to create ridges and grooves (the space between ridges) that satisfy us most, and that give Pasta Garofalo its unmistakable character.

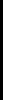

BRONZE DRAWING

IS IT ALWAYS A BETTER OPTION?

Not for those who, beyond set phrases, work with a particular goal in mind.

Most of Pasta Garofalo's shapes are bronze-drawn, because we believe that in many cases, this material provides the dough with the right porosity and colour balance. But this technique isn't always synonymous with higher quality: In the case of capellini, for example, Teflon drawing is clearly superior, because it makes the format less porous and hence stronger, even when served in broth, as per tradition. Once again, a question of choices and clarity of purpose.

DRYING

IS THERE A FIXED RULE TO ESTABLISH THE TIMING AND TEMPERATURE OF DRYING?

Not really. After all, every pasta format is a delicate and unique product, and deserves special treatment.

The drying process is decisive for delivering a product of extraordinary firmness. As you can easily imagine, the format thickness makes all the difference at this stage. For example, the correct drying of a vermicello can take twice the time as that of a spaghettino. During drying, the temperature does not stay the same, but varies - provided that utter respect for the quality of the semolina is maintained. Thus, is drying at lower temperatures - and consequently at a lower pace - necessarily better? No. To ensure a product with an optimal firmness, in fact, removing water from the dough at the right pace is absolutely key. On average, the drying temperature for Pasta Garofalo varies between 40 degrees(in the first phase) and 80 degrees (at the moment of maximum heat). Whilst everything is planned following a detailed diagram, the knowledge of the pasta maker remains fundamental. His controls during drying are essential and safeguard against unforeseen events - such as sudden climate changes.

COOKING

IS PASTA "AL DENTE" WHEN DRAINED EARLY?

No. Be careful not to confuse raw pasta with one that offers optimal firmness.

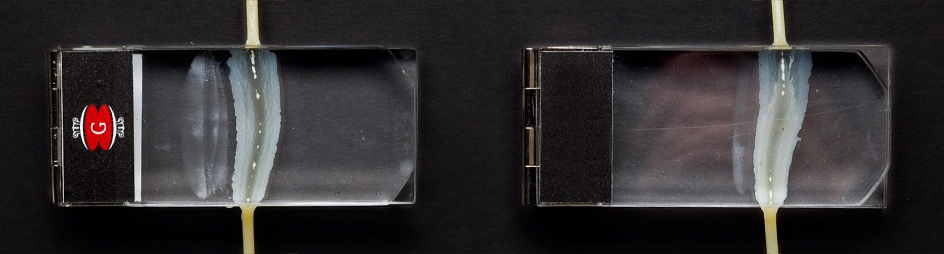

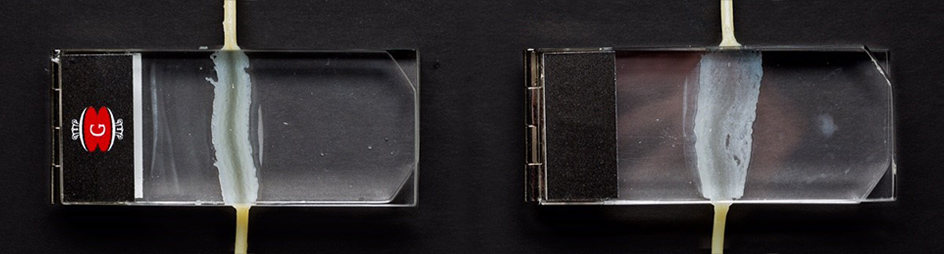

"Al dente" has nothing to do with draining the pasta early, a few minutes before its cooking time is up. It refers instead to a pasta that keeps its firmness even when completely cooked - i.e. completely hydrated. Therefore, it is an objective quality and there is an instrument for its accurate measurement: the mechanical tooth, which we also use to set the cooking times of Pasta Garofalo. A simple experiment conveys the differences in cooking firmness between two products made with different raw materials and processes. In the three photos, we see a Garofalo spaghetto (left) and one of base semolina (right) removed from the water at three different times: one minute before complete hydration, after complete hydration, and one minute after complete hydration.

COMPARISON BETWEEN DIFFERENT SEMOLINAS

One minute before:

The ridges of both spaghetti appear white, which means they are not yet fully hydrated. If you taste the pasta at this stage, both spaghetti will feel "al dente" but only because they are still raw, and the difference between both qualities is imperceptible. A comparison between two pasta types before complete cooking does not provide valid information.

Perfectly cooked:

Both spaghetti are fully hydrated (the white part - still raw - is minimal). The ridge of Garofalo's spaghetti holds its shape perfectly, whist that of basic semolina tends to yield. Thus, we already have an indication of quality here: Garofalo is superior.

Cooking time exceeded by one minute: the ridge of Garofalo's spaghetti still holds its shape, but the base semolina one is bent completely out of shape. The lower resilience of the latter is due to a lower quality of the raw material, and a less discerning production process.

CAN WE TRUST CLARITY?

Optimal pasta cooking requires 1 litre of water for every 100 grams of pasta. Water must be kept boiling throughout the entire cooking time, so as to allow homogeneous pasta rehydration. As cooking ends, the water's appearance tells us something about the quality of the pasta: if the water seems cloudy, the pasta has released its starch and its gluten structure has yielded. The cooking water of high-quality pasta remains transparent after cooking.

PGI

CAN A CENTENARY OF TRADITION BE PROTECTED?

Yes, PGI is a valid tool to protect the product and the consumer.

Pasta Garofalo is in fact Pasta di Gragnano PGI, where the protected geographical indication guarantees that our pasta formats respect precise production and quality conditions linked to the centuries old Gragnano tradition. This brand is a source of pride for us, because it keeps the good of our history alive and current, and further reassurance for our customers: the production processes are subjected not only to ours, but also to the controls by the bodies of supervision of the PGI.

Together with 13 other producers, Pasta Garofalo is part of the Gragnano Città della Pasta Consortium, which since 2019 is officially the protection consortium for the PGI brand. The unique heritage of our town, which has played a key role in the production of pasta since the sixteenth century and can boast the invention of bronze drawing, is therefore protected by the action of the Consortium, and certified by the PGI mark, present on our packs of pasta.

PASTA GAROFALO'S UNIQUE FEATURES

At the end of this process, these features are what sets our perfect pasta apart.

WHEAT TASTE AND COLOUR

We select what we consider to be the best semolina in the world, and undertake to put it on your table without altering its organoleptic characteristics.

PERFECT FIRMNESS

The maximum firmness and elasticity of the pasta, even when overcooked.

LIVELY DISH PRESENCE

Our pasta is known to keeps its colour and shape after draining, but also a few minutes later.

A STRUCTURE WITH OUTSTANDING PERSONALITY

We call this the "product architecture", which mainly emerges from the notable thickness of our shapes, delivering a unique tactile experience in the mouth.

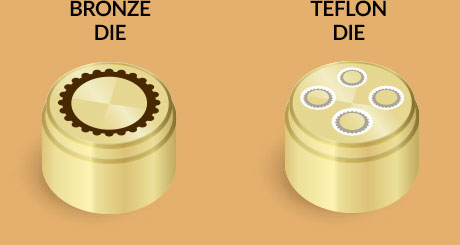

RIGHT POROSITY

This varies in all our shapes according to its most popular use: it is higher in shapes have to bind to sauces, lower in those which, for example, are served in a broth and should not absorb too much liquid.

EARLY SIGNS OF QUALITY